- Dichroic Glass

-

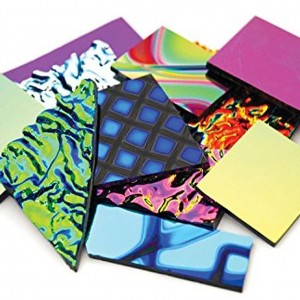

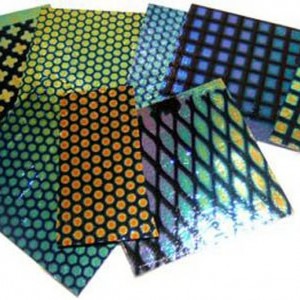

Glass that has a distinctive and intensely colorful metallic appearance which changes as the piece is viewed at different angles. Sheets of dichroic glass can be purchased and worked using fused glass techniques.

Modern dichroic glass techniques originated with NASA optics research. Preparation of dichroic glass requires technical equipment. The process requires a clean room as dust can alter the results. After the glass is cleaned of impurities, it is placed in a vacuum chamber and heated. Multiple ultra-thin laters of metallic materials like titanium, magnesium, zirconium, chromium, selenium, and tin are applied by using an electron beam to vaporize them and then let them condense on the surface of the glass in a crystal structure. As many of 50 layers may be applied, yet the coasting is still thinner than one thousandth of a millimeter. The entire process can take between two and four hours. The result is a sheet of glass with a dichroic coating which can be used by glass artists to fabricate beads and other glass objects.

Fusing dichroic glass is an unpredictable process because the glass and metallic coating react differently to heat. The glass heats more quickly than the coating, separating the two layers. When the piece cools, the glass and coating contract at slightly different rates. The original configuration of the coating can never be recreated, thus each dichroic glass piece is unique. The result is an irregular surface which adds to the refraction of light. This effect is enhanced at higher temperatures.